SPARK EROSION

EDM Spark Erosion

EDM Spark Erosion

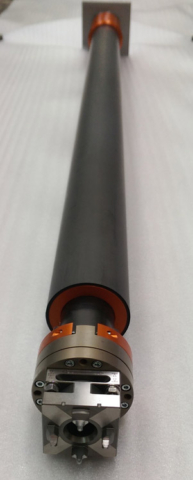

Our linear EDM spark erosion capacity gives us an unparalleled advantage in both accuracy and productivity.

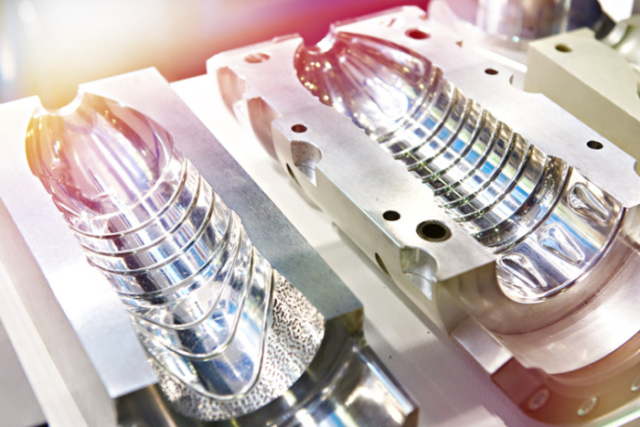

As well as more conventional mould tool applications, we have specialist experience in producing instrumentation and calibration features for areas including aerospace thermocouple routing on complex surfaces and production of ultrasonic target features in composite alloy components.

Investment in HyperMill Electrode software enables us to extract data from mould tool models and generate a suite of electrodes efficiently.

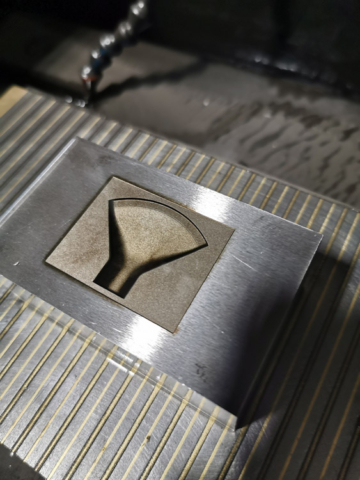

Micro EDM and Hole Drilling

To complement our range of EDM services, we have a Sarix T1-T4 EDM hole drill machine for producing holes from 0.1mm to 0.4mm diameter. With its fine control, the machine is also suitable for producing micro EDM features.

Capacity

- Sodick AM3L Linear Die Sink

- SARIX T1-T4 Micro hole drill and Micro EDM

EDM Spark Erosion

EDM Spark Erosion