WIRE EROSION

Wire Erosion

Wire Erosion

With nearly 25 years of wire erosion experience, Solutek Ltd is at the forefront of applied wire erosion technology.

We have the expertise, coupled with premium equipment, to offer the complete wire erosion service from product/process development to full mass production.

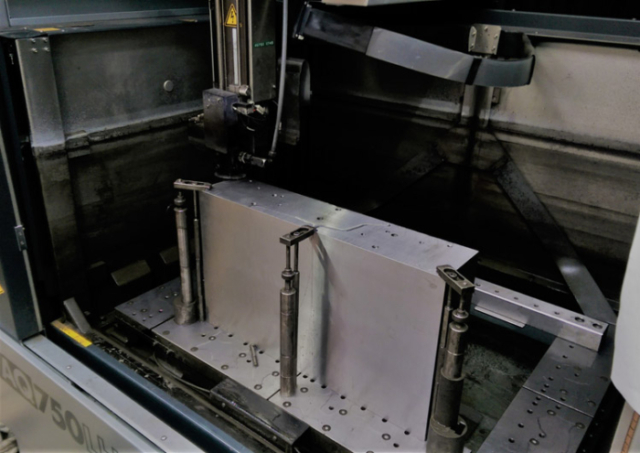

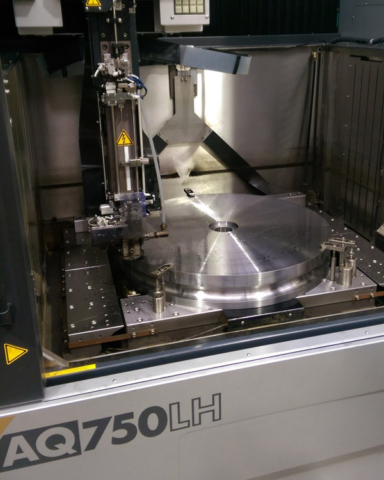

Our wide ranging capacity enables us to machine tiny work pieces to large components up to 600mm tall with our range of Sodick machines including a AQ750LH (X axis 750mm, Y Axis 500mm Z axis 600mm). Sodick Linear motor technology offers repeatable, high accuracy.

Our robust set up practices and process knowledge precedes our quality reputation. We are one of the UK’s leading Wire EDM sub-contract service providers.

If you are unfamiliar with wire erosion and are considering using this process as a new or alternative to a conventional machining process, please do not hesitate to contact us. We can advise on process planning, datum features, start holes and stock allowances.

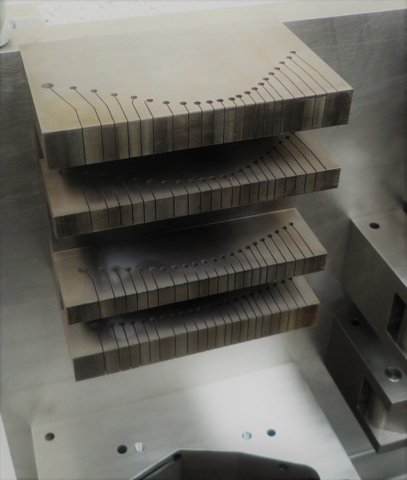

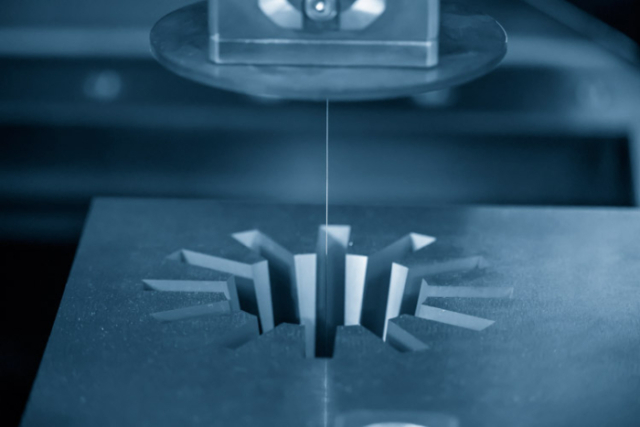

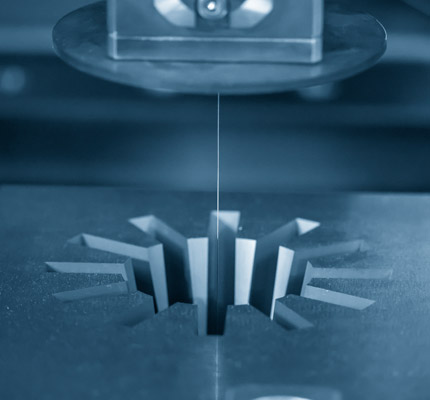

Wire erosion is a non-contact process with no cutting forces. As a result this can simplify setups for complex machining, making one off and small quantities. Small to large batch work can be fixtured accordingly to reduce loading time.

Wire erosion will cut conductive materials in hard or annealed conditions.

Example of the range of materials that we have machined:

|

|

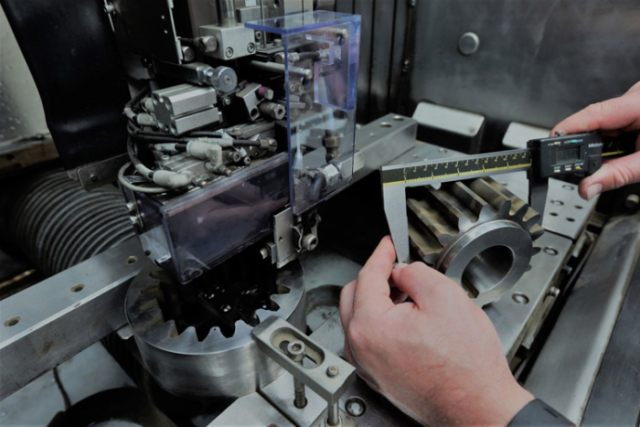

Dependant on application, we can use a range of wire diameters from 0,1mm to 0,3mm

Wire erosion’s primary accuracy is typically within 0,04mm (dependant on material and work piece thickness). Additional cuts can improve surface down to 0.25Ra and accuracy to within +/-0,002mm.

Capacity

- Sodick AQ750LH X750mm Y500mm Z600mm

- Sodick VZ300 X350mm Y250mm Z220mm

- Sodick AQ535 X550mm Y350mm Z300mm

- Sodick AQ325L X350mm Y250mm Z220mm

Wire Erosion

Wire Erosion